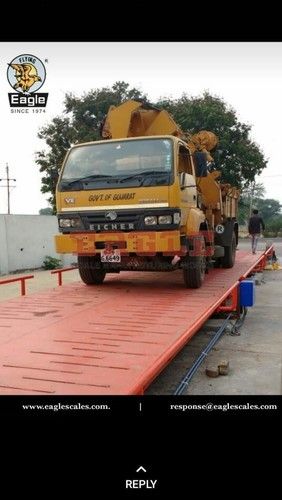

Electronic Weigh Bridge

Product Details:

- Display Type LED / LCD

- Size Customized Standard: 7.5m x 3m to 18m x 3m

- Power Source Electric / Battery

- Application Vehicle Weighing, Logistics, Mining, Construction

- Interface RS232 / Ethernet

- Automatic Grade Fully Automatic

- Function Weighing Trucks and Heavy Vehicles

- Click to View more

Electronic Weigh Bridge Price And Quantity

- 400000.00 - 1100000.00 INR/Piece

- 1 Piece

Electronic Weigh Bridge Product Specifications

- Vehicle Weighing, Logistics, Mining, Construction

- Grey/Blue (Standard)

- RS232 / Ethernet

- 230V AC, 50Hz stabilized

- Fully Automatic

- Fully Electronic Weighbridge

- Weighing Trucks and Heavy Vehicles

- Other

- Platform Scale

- Industrial, Commercial

- Digital / LED / LCD

- 5 Ton to 200 Ton

- Up to 0.02%

- LED / LCD

- Customized Standard: 7.5m x 3m to 18m x 3m

- Electric / Battery

- Varies as per model, up to 200 tons

Electronic Weigh Bridge Trade Information

- 20 Piece Per Month

- 5-7 Days

- North America, Middle East, Africa, Asia

Product Description

In order to maintain the existing goodwill of the organization, we are providing a wide variety of ELECTRONIC WEIGH BRIDGE. This product is manufactured using excellent quality raw materials and progressive technology, in adherence with the industry norms. The entire range is made available in customized dimensions as per the specifications provided by our clients. The offered ELECTRONIC WEIGH BRIDGE is tested under the supervision of our professionals. We also provide repairing services of this product. The provided assortment is offered to our clients at a market leading rates.

Features:

-

Perfect strength

-

Compact design

-

Accurate dimensions

-

Corrosion resistance

Precision Weighing for Heavy Duty Applications

Ensure dependable and precise measurement of trucks and heavy vehicles with accuracy levels reaching 0.02%. This weigh bridge is tailored for applications demanding accuracy, such as vehicle logistics, mining material handling, and construction reporting, where precision matters most.

Customizable and Versatile Installations

Choose from a spectrum of size options, starting from 7.5m x 3m up to 18m x 3m, to meet your specific site requirements. Standard color options of grey and blue integrate seamlessly with industrial environments, and the bridges interface flexibility supports smooth data transfer across RS232 or Ethernet.

Fully Automated and Easy to Operate

Designed with automated features, the Electronic Weigh Bridge streamlines the weighing process. Convenient controls and digital displays (LED/LCD) provide quick readouts and error-free operation, minimizing the need for extensive manual intervention.

FAQs of Electronic Weigh Bridge:

Q: How does the Electronic Weigh Bridge ensure high accuracy in vehicle weighing?

A: It utilizes advanced platform scale sensors, robust construction, and digital displays to consistently deliver measurements with accuracy up to 0.02%, supporting reliable results for loads from 5 tons to 200 tons.Q: What types of vehicles and industries can use this weigh bridge?

A: It is suitable for weighing trucks, heavy-duty vehicles, and machinery used in logistics, mining, construction, and commercial transport environments, making it ideal for industrial and commercial sites.Q: When should a business consider installing a weigh bridge?

A: A weigh bridge is recommended when precise measurement of vehicle loads is required for legal compliance, inventory control, or operational efficiency in industries like mining, logistics, and construction.Q: Where can the weigh bridge be installed, and are sizes customizable?

A: The bridge can be deployed in industrial yards, manufacturing plants, and logistics hubs. Sizes can be tailored to requirements, with standard dimensions ranging from 7.5m x 3m up to 18m x 3m.Q: What is the typical process for weighing a truck using this system?

A: The vehicle is positioned on the platform; the weigh bridge automatically records the weight and displays it on LED or LCD monitors. Data is transferred via RS232 or Ethernet for processing or archiving.Q: How is the weigh bridge powered, and what display options are available?

A: It operates on a stabilized 230V AC power source, with optional battery backup. Users can select LED, LCD, or digital monitors, ensuring flexible readability in different lighting conditions.Q: What are the key benefits of using an electronic weigh bridge for industrial applications?

A: Key advantages include precision weighing, automated operation, compatibility with data systems, customizable size options, and robust performance for heavy vehicles, optimizing workflow and ensuring accurate record-keeping.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+